Sustainable industries through digital supply chains?

06.03.2023

By Calvin Hanebeck (Uni Potsdam), Gereon Mewes (Minerva University) and Stefanie Kunkel (RIFS)

Digitalisation has transformed the way we communicate and collaborate with friends, family, and colleagues. In a similar vein, digitalisation in industry – the so-called industry 4.0 – is expected to transform the way firms and their suppliers collaborate in global supply chains. Considering that 25 percent of global emissions in 2021 were generated by industry (IEA): Can industry 4.0 play a role in greening industrial supply chains? Researchers at the Research Institute for Sustainability (RIFS) at the Helmholtz Centre Potsdam explored the opportunities and risks of digital supply chains for environmental sustainability. In short: sustainability does not simply occur as a by-product of digitalization. Firms should aim to increase sustainability levels in their supply chain – whether through digital or non-digital means.

Background

Supply chains are becoming increasingly digital as firms move towards industry 4.0 in their operations. They create so-called cyberphysical systems to enable interconnectivity and autonomous production across firms and even countries in global supply chains. These digital supply chains are expected to reduce costs for and foster collaboration between firms in different countries. They are also expected to promote the exchange of information about environmental sustainability, such as energy use and emissions data, and facilitate collaboration on topics like sustainable innovation and circular economy across firms. In light of these possibilities, the question arises how far firms have already realised digital supply chains, and how they affect sustainability in practice. To answer these questions and gain insights into firms’ experiences with digital supply chain collaboration researchers from the Research Institute for Sustainability (RIFS) in Potsdam conducted a study interviewing Chinese suppliers and international buying firms in the electronics sector. This article summarises some of their findings.

Varying levels of digital maturity

Not all firms have the same level of digital maturity in their supply chains. In the study, the RIFS researchers distinguished between low, intermediate, and high digital maturity in digital supply chain collaboration. Low digital maturity is associated with the use of telephone and paper communication, intermediate digital maturity with email, office software, electronic data interchange, or Enterprise Resource Planning (ERP) systems, and high digital maturity with the use of industry 4.0 key technologies, such as the internet of things (IoT), big data analytics (BDA), artificial intelligence (AI), cloud computing, and additive manufacturing.

Digital maturity in collaboration. Source: own elaboration based on Bickauske et al. (2020) and Shao et al. (2021).

Opportunities, risks, and obstacles of digitalisation for sustainable supply chain collaboration?

The researchers asked about the opportunities, risks, and obstacles related to digitalisation for sustainable supply chain collaboration.

Opportunities

Firms perceived digitalisation as a facilitator for green innovation and knowledge transfer. There was also interest in the role of digital technologies to facilitate measurement of CO2 emissions along the supply chain, although firms were not aware of specific digital solutions for such measurements. Another opportunity cited was the environmental optimisation of logistics chains, such as shortening truck fleet routes through algorithmic optimisation. Lastly, digital technologies were expected to help increase material circularity. Several firms mentioned the expectation of enhanced recycling collaboration supported by digital supply chains, for instance, by tracking and reusing containers and reusable packaging, which could reduce the amount and cost of packaging.

Risks

The interviews revealed that, despite high expectations, neither suppliers nor buying firms intensively used digital technologies for sustainability collaboration in the supply chain. While most firms recognised the potential of digital supply chains for energy and material efficiency gains, they did not yet realise these potentials. Instead, they seemed to use digital technologies for marketing or economic optimisation purposes rather than for sustainability. This poses a risk of optimising and accelerating unsustainable business models through digital supply chains, instead of fostering transformative business models. Moreover, digital rebound effects may occur, where efficiency improvements make energy use cheaper, which may, in the worst case, lead to increased energy consumption.

Obstacles

Firms mentioned that a shortage of skilled personnel made it difficult to implement digital sustainability solutions. Additionally, some firms were hesitant to use more digitally mature technologies due to concerns about data safety. The digital infrastructure was perceived as insecure for sensitive intellectual property, such as industrial innovations, to be shared. Finally, weak regulations contributed to limited interest in monitoring environmental indicators.

Conclusion on digital supply chains

The researchers concluded that there was currently limited digital supply chain collaboration on sustainability. Firstly, few firms appeared to have a high level of digital maturity in supply chain collaboration at all. Secondly, a lack of incentives for firms to collaborate on sustainability through digital supply chains was identified. As a result, digital technologies were primarily reported to be used for economic purposes. This was found to carry the risk of improving unsustainable business models and creating rebound effects. Thirdly, the supply chain was not considered in its entirety. Upstream suppliers (closer to the sourcing of raw materials) were rarely taken into account in digital supply chain collaboration, even though sustainability risks may be high.

A way forward? Recommendations for more sustainable digital supply chains

To enhance environmental sustainability in digital supply chains, the RIFS researchers make the following three recommendations for policy makers and businesses:

- Foster digital environmental upgrading: Digitally mature firms being more active in the sustainability sphere should support less mature firms in collaborating on sustainability through digital technologies, for instance, by fostering sustainability data gathering and exchange, providing (online) trainings on sustainability practices, and transferring knowledge about more environmentally sustainable operations.

- Create economic and environmental win-win situations: Firms should create a business case for (digital) sustainability collaboration. They should develop strategies that both save money and enable more environmentally friendly operations through digital collaboration, such as by monitoring energy use across firms to identify cost savings potential.

- Improve legal environment: Policymakers should implement regulation to ensure that firms have an obligation to create sustainable (digital) supply chains (positive steps in this direction being the EU Proposal on Corporate Sustainability Due Diligence Directive (CSDD) and the EU Corporate Sustainability Reporting Directive (CSRD)).

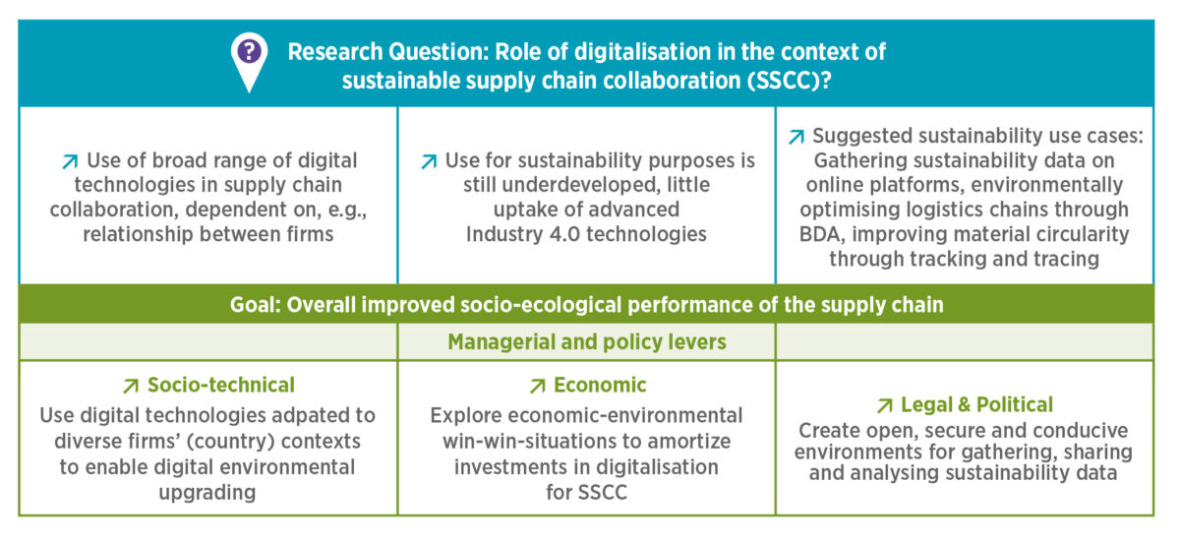

Graphical summary of the study Industry 4.0 in sustainable supply chain collaboration: Insights from an interview study with international buying firms and Chinese suppliers in the electronics industry

This article was first published on 1 March, 2023, on the HIIG blog.